Category

WATER DRINKING LINECLEANING SYSTEM

LG365 Intelligent Waterline Control System

●Supporting manual and automatic flushing management for 64 waterlines;

●Supporting setting automatic flushing time, flushing interval days, andflushing duration for each waterline;

●Equipping with a 30g/hour ozone generator that injects ozone, utilizingozone to decompose biofilm on pipe walls to achieve sterilization and disinfection;

●Performing water consumption analysis for each waterline after automaticflushing;

●Supporting manual and automatic dosing control for waterlines;

●Equipping pressure regulators at the front end of each waterline with solenoid valves, enabling automatic flushing of each waterline individually;

●Optional level sensors can be installed at the end of each waterline, enablingwater shortage alarms and automatic high-pressure water replenishmentupon water shortage.Additionally, optional drain solenoid valves can beequipped for automatic drainage.

Read More

●LG530 Support egg belt width L=150mm;

●LG536 support egg collector bracket width 540mm~800mm;Counting accuracy of 99.5%;

●Adopting machine vision and artificial intelligence technology;

●LG530 Egg Counting Controller supports 16 chicken houses in seriescounting mode, counting the number of eggs per house,16 columnsegg counting mode, and querying historical egg collection data;

●LG530 is used with LG535 or LG536.When the central egg collectoris installed higher,LG 530 egg counting controller can be installedunder the egg collector, which is convenient to view and operate;

●Supporting uploading data to Digital Farming Cloud Platform, you couldview egg collection data via computer and cell phone;

●The centralized egg collection visual counting system supports 2 counting methods: single counting and tandem subtraction counting.

Read More

LG800 INTELLIGENTCLIMATE CONTROLLER

LG800 intelligent climate controller adopts the latest intelligent control technology.integrating functions such as ventilation, temperature, humidity, lighting, heating,cooling, feeding, and alarm.

Read More

When designing poultry lighting,Little Giant takes into account the physiological characteristics of the poultry itself to avoid the impact of lighton the poultry.Therefore, Little Giant poultry lights have the followingcharacteristics

Read More

Customers can view thetemperature, humidity,negative pressure, airinlets opening angle,ventilation level, No. offans in operation, foodconsumption and waterconsumption in real time.

Read More

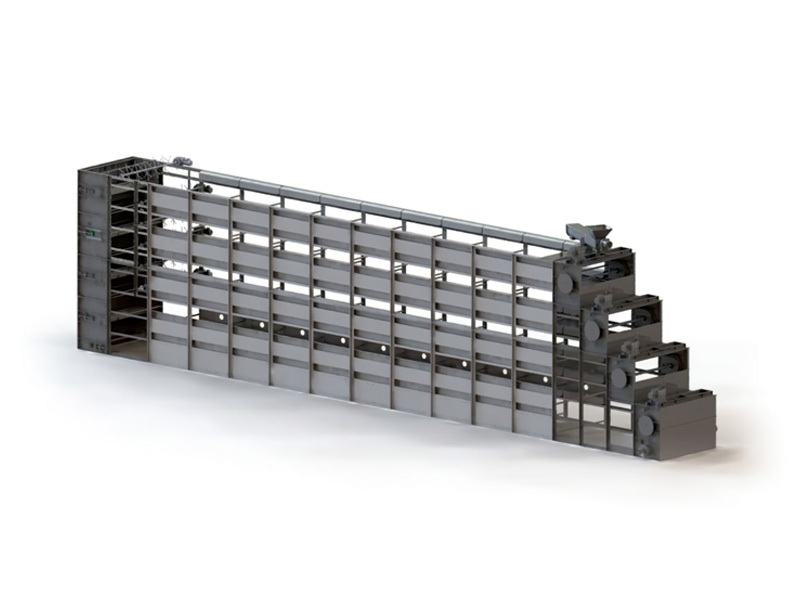

Chicken manure air drying equipment

● No additional heat source is needed, and the chicken manure is dried by the exhaust air of the chicken house;

● The moisture content in fresh chicken manure can be reduced to about 20% within 48 hours;

● Modular products, can be combined with customer needs and the actual situation of the site for tailor-made design, to create benefits for customers;

● Modular design is quick to install, intelligent and efficient. Product low energy consumption, low failure;

● High stability, high life, two low two high performance advantages;

● Through the modular design, the manure treatment is cleaner and more effective, while reducing the transportation cost, the storage is more convenient, effectively reducing the cost and saving resources.

Read More

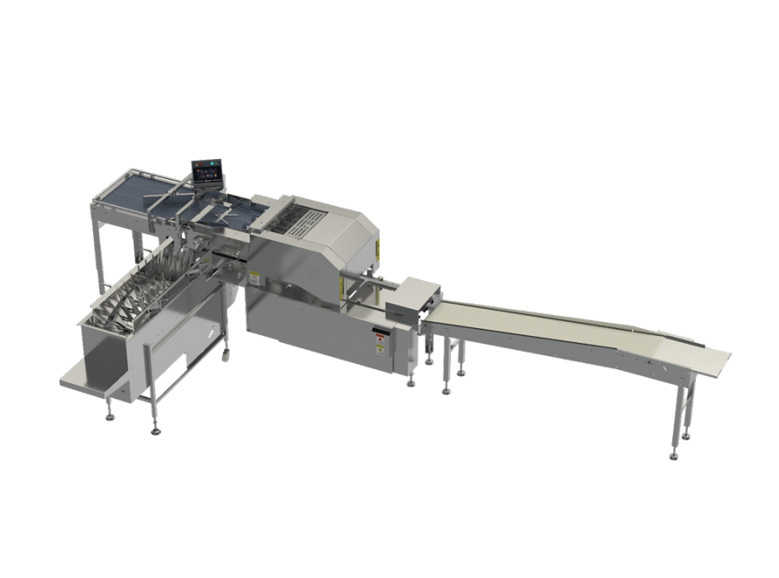

The poultry egg palletizing machine series products are specifically designed for packaging poultry eggs that need to be placed in pallets. The theoretical design total output is 36,000, 72,000, 80,000, 100,000, and 120,000 poultry eggs per hour. It replaces manual palletizing, greatly improving egg collection efficiency and reducing labor intensity.

Read More

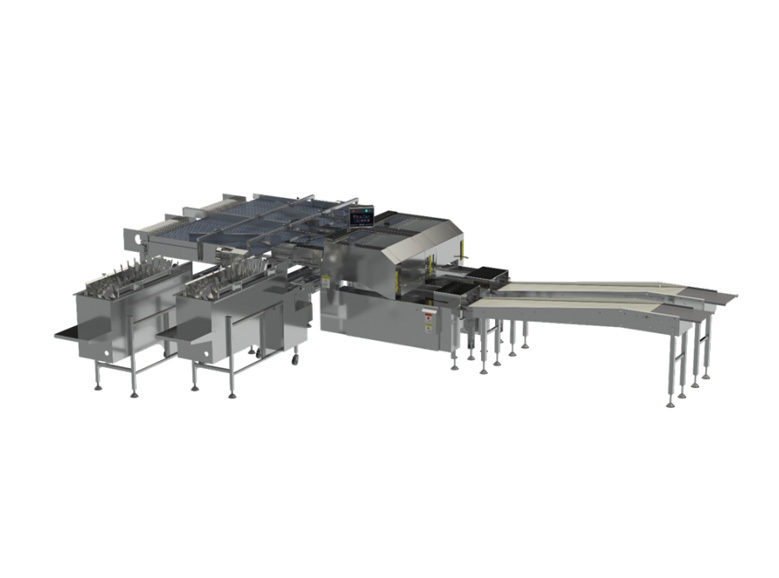

The poultry egg palletizing machine series products are specifically designed for packaging poultry eggs that need to be placed in pallets. The theoretical design total output is 36,000, 72,000, 80,000, 100,000, and 120,000 poultry eggs per hour. It replaces manual palletizing, greatly improving egg collection efficiency and reducing labor intensity.

Read More

The poultry egg palletizing machine series products are specifically designed for packaging poultry eggs that need to be placed in pallets. The theoretical design total output is 36,000, 72,000, 80,000, 100,000, and 120,000 poultry eggs per hour. It replaces manual palletizing, greatly improving egg collection efficiency and reducing labor intensity.

Read More

wz@cdxjr.com

wz@cdxjr.com

+86 180 5329 3175

+86 180 5329 3175