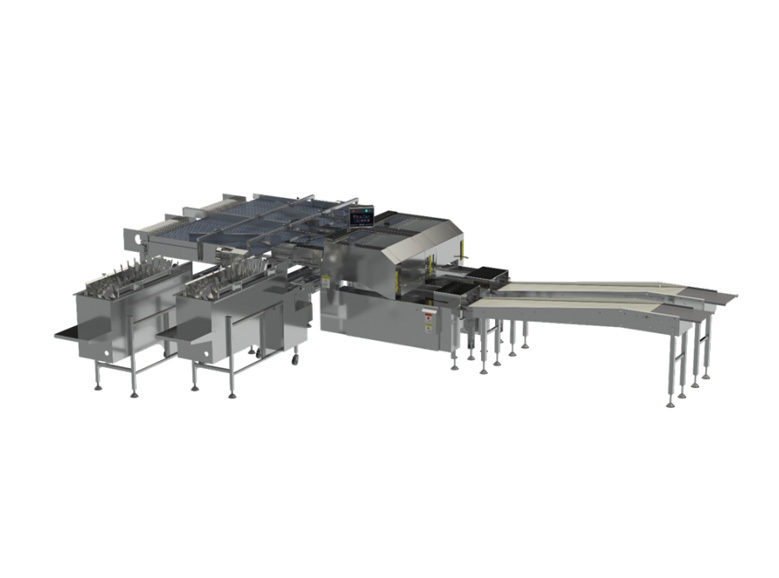

BFP-720

key word:

Category:

Product Description

[BFP-720] can be used with feeding belt with height between 930 and 1050mm

Product Configuration

According to the actual use of factories and farms, BFP series egg loading machine can be equipped with plastic egg tray automatic supplier, palletizer, etc.

|

Supply the egg tray device, manually put the egg tray, and supply the egg tray with the signal to be held. |

Docking the central egg feeding line can realize linkage control with the central egg feeding line, automatically adjust the egg feeding speed of the loading machine through induction, avoid egg accumulation, reduce broken eggs and improve loading efficiency. |

Egg conveying adjust the size of the head, neatly down the plate, to ensure gentle, to avoid broken eggs. |

|

After the egg tray is released, the egg tray is transported to the bottom of the tray module to receive the egg tray, and flows into the conveying line to flow away. |

After loading, the eggs are transported to the packing table for manual packing, with adjustable height and ergonomics. |

Equipped with control electric box and touch control screen, it can adjust the efficiency of egg loading, store and display egg processing related data. |

The egg loading machine series is suitable for use in environments with a temperature of 0 ° to +35 ° C and a relative humidity of 40% to 85%.

The required power supply is 380V(± 10%),3 phase, 50/60Hz.

The connection value of the standard version is 1.3KW/2.5KW.

Configuration Scenario Chart

RECOMMENDED PRODUCTS

MESSAGE BOARD

wz@cdxjr.com

wz@cdxjr.com

+86 180 5329 3175

+86 180 5329 3175